Companies

N.Z. Supermarket Tests Bring-Your-Own Meat Containers

A New Zealand supermarket is testing an unusual solution to waste management: customers may bring their own reusable containers to the store to package fresh meat purchases. For the time being, the test is limited to the butcher and seafood counters, but if successful could be extended to bakery, deli and bulk foods. Other stores, however, are casting a skeptical eye at the initiative, mainly because of concerns about food safety, hygiene and correct measurement of weight. The store says there are restrictions: containers must have lids and be suitable for weighing and handling; price labels must be placed on containers for security; and customers must provide clean containers and accept the safety risk. ]

Advanced Technology Is Tackling Waste All Along The Food Chain

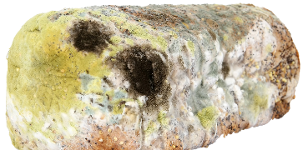

Technology is playing an increasingly important role in dealing with America’s $218 billion annual food waste problem. It is being gradually implemented upstream to track food as it moves from farm to processor to distributor to store. At the other end of the line, where disposal happens, innovations such as digesters (Waste 2-0 left) provide alternatives to landfill and “waste-to-energy.” A key to wasting less food is understanding how much food is being wasted and what percentage of the available food that represents. Farmers, processors, restaurants, bakeries and others can use this information to better understand the financial costs and implement solutions. Older technology also plays a role: refrigeration, freezing, and drying all extend the shelf life of food to prevent waste.

Technology is playing an increasingly important role in dealing with America’s $218 billion annual food waste problem. It is being gradually implemented upstream to track food as it moves from farm to processor to distributor to store. At the other end of the line, where disposal happens, innovations such as digesters (Waste 2-0 left) provide alternatives to landfill and “waste-to-energy.” A key to wasting less food is understanding how much food is being wasted and what percentage of the available food that represents. Farmers, processors, restaurants, bakeries and others can use this information to better understand the financial costs and implement solutions. Older technology also plays a role: refrigeration, freezing, and drying all extend the shelf life of food to prevent waste.

Australia’s Science Agency Pulverizes Surplus Broccoli To Make Beverage Powders

Australian vegetable farmers routinely leave 10 to 20 percent of their crop in the field as unsaleable surplus to be ploughed back into the soil. The country’s scientific research agency (CSIRO), however, has been working on ways to transform surplus produce from waste into nutritious, edible vegetable powders to fortify beverages, including coffee. Its latest coffee additive project – it has already tried beetroot, coconut, turmeric, and blue algae – is broccoli, a nutrient-rich vegetable with plenty of fiber, vitamins A, B1 and B6, potassium, zinc, magnesium, and other healthful ingredients. For coffee, the broccoli powder is added to a shot of espresso before the steamed milk is added, then also sprinkled on top. According to one CSIRO scientist, two tablespoons of broccoli powder is equivalent to one serving of vegetables.

Australian vegetable farmers routinely leave 10 to 20 percent of their crop in the field as unsaleable surplus to be ploughed back into the soil. The country’s scientific research agency (CSIRO), however, has been working on ways to transform surplus produce from waste into nutritious, edible vegetable powders to fortify beverages, including coffee. Its latest coffee additive project – it has already tried beetroot, coconut, turmeric, and blue algae – is broccoli, a nutrient-rich vegetable with plenty of fiber, vitamins A, B1 and B6, potassium, zinc, magnesium, and other healthful ingredients. For coffee, the broccoli powder is added to a shot of espresso before the steamed milk is added, then also sprinkled on top. According to one CSIRO scientist, two tablespoons of broccoli powder is equivalent to one serving of vegetables.

Tesco Sells Greener Lemons To Help Prevent Food Waste At Home

British supermarket chain Tesco has relaxed its rules on the color quality of lemons it sells to prevent food waste at home. The company is selling lemons that are slightly green to extend the shelf like by an extra couple of days. According to the company, the lemons are as crisp and zesty as the fully yellow versions. Tesco imports most of its lemons from South Africa, whose lemon harvesting season begins in late June. The company will now take the greener South African lemons earlier than usual to keep supplies going.

British supermarket chain Tesco has relaxed its rules on the color quality of lemons it sells to prevent food waste at home. The company is selling lemons that are slightly green to extend the shelf like by an extra couple of days. According to the company, the lemons are as crisp and zesty as the fully yellow versions. Tesco imports most of its lemons from South Africa, whose lemon harvesting season begins in late June. The company will now take the greener South African lemons earlier than usual to keep supplies going.

EU Clarifies Rules On Surplus Food Used As Animal Feed

Surplus food cannot be categorized as food waste when it is used as animal feed, according to revised European Union rules known as the Waste Framework Directive. Substances already covered by feed legislation would not be unnecessarily included in the scope of waste legislation, a clarification advocated by the trade group European Former Foodstuff Processors Association (EFFPA), which represents companies that turn foodstuffs into animal feed. According to an EFFPA representative, under the old rules Europe-wide processors of surplus food occasionally would have had their operations interrupted by environmental control authorities who incorrectly interpreted former foodstuffs as a waste.

Surplus food cannot be categorized as food waste when it is used as animal feed, according to revised European Union rules known as the Waste Framework Directive. Substances already covered by feed legislation would not be unnecessarily included in the scope of waste legislation, a clarification advocated by the trade group European Former Foodstuff Processors Association (EFFPA), which represents companies that turn foodstuffs into animal feed. According to an EFFPA representative, under the old rules Europe-wide processors of surplus food occasionally would have had their operations interrupted by environmental control authorities who incorrectly interpreted former foodstuffs as a waste.

New App Helps Reduce Food Waste With Smart Shopping, Storage, Cooking

Silicon Valley-based Chefling, Inc., has created a smartphone app that helps consumers minimize daily food waste. Available now on the App Store and Google Play, the app includes food inventory organization, intuitive recipe suggestion, and shopping list management. According to the company, consumers using the app can track and make the most out of recently purchased and existing ingredients in the pantry. The app monitors the freshness of added foods, notifies the consumer when foods are about to expire, and suggests recipes for the foods already purchased. The app also features integration with voice assistant devices like Amazon Echo and Google Home: it will add foods to a shopping list and provide step-by-step cooking instructions.

Silicon Valley-based Chefling, Inc., has created a smartphone app that helps consumers minimize daily food waste. Available now on the App Store and Google Play, the app includes food inventory organization, intuitive recipe suggestion, and shopping list management. According to the company, consumers using the app can track and make the most out of recently purchased and existing ingredients in the pantry. The app monitors the freshness of added foods, notifies the consumer when foods are about to expire, and suggests recipes for the foods already purchased. The app also features integration with voice assistant devices like Amazon Echo and Google Home: it will add foods to a shopping list and provide step-by-step cooking instructions.

British Meal Powder Import Claims U.S. Market Success

A British company whose mission three years ago was to create a “nutritionally complete, convenient, affordable food” with minimum environmental impact, says its plant-based powdered meals are succeeding in the U.S. because they are clean label, healthful, and help eliminate food waste and hunger. Huel claims to have sold more than 17 million meals – $10 million in sales – since its debut here last summer. The company says its product is not a supplement like other powders, but a complete food that contains all the proteins, carbs and fats needed in addition to 100 percent of the FDA's "Daily Values" of all 27 essential vitamins and minerals. Huel blends oats, pea protein, flaxseed, brown rice protein, medium-chain triglycerides (MCTs) from coconut, and other ingredients. The powder sells for $66 for two bags (28 meals total, 14 per bag, only $2.36/meal).

A British company whose mission three years ago was to create a “nutritionally complete, convenient, affordable food” with minimum environmental impact, says its plant-based powdered meals are succeeding in the U.S. because they are clean label, healthful, and help eliminate food waste and hunger. Huel claims to have sold more than 17 million meals – $10 million in sales – since its debut here last summer. The company says its product is not a supplement like other powders, but a complete food that contains all the proteins, carbs and fats needed in addition to 100 percent of the FDA's "Daily Values" of all 27 essential vitamins and minerals. Huel blends oats, pea protein, flaxseed, brown rice protein, medium-chain triglycerides (MCTs) from coconut, and other ingredients. The powder sells for $66 for two bags (28 meals total, 14 per bag, only $2.36/meal).

Dairy Farmers Can Turn Waste Products Into Electricity, Methane Gas

A recent podcast sponsored by the American Farm Bureau Federation presented ideas for recycling inedible products from dairy farms. One farmer in Pennsylvania, for example, who is participating in the No Taste for Waste campaign uses an anaerobic digester – the original purpose was to reduce odor – to recycle food waste into enough electric power and methane to supply the farm and roughly 100 other homes. It’s a better way to deal with waste than sending it to a landfill. But another solution is to, whenever possible, channel surplus food “to those that are less fortunate” and to animal feed processors.

A recent podcast sponsored by the American Farm Bureau Federation presented ideas for recycling inedible products from dairy farms. One farmer in Pennsylvania, for example, who is participating in the No Taste for Waste campaign uses an anaerobic digester – the original purpose was to reduce odor – to recycle food waste into enough electric power and methane to supply the farm and roughly 100 other homes. It’s a better way to deal with waste than sending it to a landfill. But another solution is to, whenever possible, channel surplus food “to those that are less fortunate” and to animal feed processors.

Student’s Invention Helps Fight Food Waste At Home

Eleven-year-old British student Rumaan Malik didn’t like it when apples went bad while sitting in the fruit bowl at home. Concerned about wasted food, she invented what she calls the “Alarm Cup,” in the process winning online supermarket Ocado’s Food Waste Challenge award. The grocer then partnered with design website, Little Inventors, to create a prototype of the cup. Her invention sounds an alarm before the fruit goes bad, thereby keeping it out of the trash. The cup also has a small touchscreen display with icons for different produce, and recipes such as apple crumble and banana bread that put aging fruits to good use. [Image Credit: © LittleInventors.org]

Eleven-year-old British student Rumaan Malik didn’t like it when apples went bad while sitting in the fruit bowl at home. Concerned about wasted food, she invented what she calls the “Alarm Cup,” in the process winning online supermarket Ocado’s Food Waste Challenge award. The grocer then partnered with design website, Little Inventors, to create a prototype of the cup. Her invention sounds an alarm before the fruit goes bad, thereby keeping it out of the trash. The cup also has a small touchscreen display with icons for different produce, and recipes such as apple crumble and banana bread that put aging fruits to good use. [Image Credit: © LittleInventors.org]

Expenditures On Food Waste Reduction Significantly Reduce Operating Costs

Company’s Advanced Monitoring Technology Ensures Food Freshness

California-based Zest Labs, a specialist in food monitoring technologies, is marketing its Zest Fresh solution using analytics and data to determine the remaining freshness of transported food and to enable proactive decision-making throughout the supply chain. Zest Fresh reduces or eliminate waste at its source by harnessing the right data at the right time – in the field at harvest, for example, in the case of fresh produce. The technology uses a “freshness metric" dubbed the Zest Intelligent Pallet Routing (ZIPR) Code to provide growers, shippers and retailers with the actual remaining shelf life of food products, including meat, poultry, and fish. This enables intelligent routing that ensures each pallet meets the retailer’s freshness requirements. [Image Credit: © Zest Labs]

California-based Zest Labs, a specialist in food monitoring technologies, is marketing its Zest Fresh solution using analytics and data to determine the remaining freshness of transported food and to enable proactive decision-making throughout the supply chain. Zest Fresh reduces or eliminate waste at its source by harnessing the right data at the right time – in the field at harvest, for example, in the case of fresh produce. The technology uses a “freshness metric" dubbed the Zest Intelligent Pallet Routing (ZIPR) Code to provide growers, shippers and retailers with the actual remaining shelf life of food products, including meat, poultry, and fish. This enables intelligent routing that ensures each pallet meets the retailer’s freshness requirements. [Image Credit: © Zest Labs]

Food Freshness Card Honored As Best New Food Safety Solution

The Food Freshness Card developed by Natures Natural Solutions was recently named the Best New Safety Solution by United Fresh. The card is laboratory and commercially tested to keep food fresher longer, according to the company, whose mission is to address the global problem of food waste and spoilage, “inside and outside of a refrigerator.” The Food Freshness Card combines specific frequencies, elements and customized programs and encodes information on a substrate enabling it to extend shelf life. It can prolong freshness at any point in the food chain: from the farm to packaging, pallet, container, distributor and retailer. The company says supermarkets that use the card average an instant 20 percent decrease in shrink/spoilage and prevent more than $3,000 a month per store in waste. [Image Credit: © FoodFreshnessCard.com]

The Food Freshness Card developed by Natures Natural Solutions was recently named the Best New Safety Solution by United Fresh. The card is laboratory and commercially tested to keep food fresher longer, according to the company, whose mission is to address the global problem of food waste and spoilage, “inside and outside of a refrigerator.” The Food Freshness Card combines specific frequencies, elements and customized programs and encodes information on a substrate enabling it to extend shelf life. It can prolong freshness at any point in the food chain: from the farm to packaging, pallet, container, distributor and retailer. The company says supermarkets that use the card average an instant 20 percent decrease in shrink/spoilage and prevent more than $3,000 a month per store in waste. [Image Credit: © FoodFreshnessCard.com]

Tomatoes With Longer Shelf Life Will Soon Reach Market

According to the U.S. Environmental Protection Agency, tomato food waste costs American households $2.3 billion annually. But California-based food technology company Arcadia Biosciences and hybrid seed developer Shriram Bioseed may have come up with a solution. They announced development of extended shelf life (ESL) tomatoes with improved yield and fruit quality. The new hybrids are in the pre-commercial, wide-area field testing stage with anticipated launch in 2019. Arcadia used a non-GM advanced screening and breeding technique called TILLING to screen genetic variations that allow tomatoes to fully ripen on the vine yet remain durable enough to survive the packing and shipping process.

British Company To Open Waste Food Catering Business

A British non-profit company is planning to use unused food to offer catering and meal services to people, businesses and organizations, beginning in September. Real Junk Food Manchester’s program will focus on commercial outside catering services such as buffets and hot meals. The venture will be housed in a large commercial kitchen in partnership with a local social housing provider and will collaborate with local charity and public-sector groups to supply meals to vulnerable people across the city. RJFM opened its first waste food pay-as-you-feel restaurant concept last year as a short-term pop-up concept and doubled in size.

A British non-profit company is planning to use unused food to offer catering and meal services to people, businesses and organizations, beginning in September. Real Junk Food Manchester’s program will focus on commercial outside catering services such as buffets and hot meals. The venture will be housed in a large commercial kitchen in partnership with a local social housing provider and will collaborate with local charity and public-sector groups to supply meals to vulnerable people across the city. RJFM opened its first waste food pay-as-you-feel restaurant concept last year as a short-term pop-up concept and doubled in size.

Students Turn Food Processing Waste Into Profit Center

Danish technology students who were asked to find a sustainable process to recycle carrot peels and pulp have come up with a way to turn to it into flour. Vegetable supplier Greens Wholesale generates 100 tons of biological waste every month as it produces fresh juices and produce. Much of the waste is converted to biogas or fertilizer, but the company wanted to optimize its production process to reduce costs and perhaps turn a profit. Turning carrot waste into flour was the winning idea: it can replace up to half of the wheat flour in a recipe. The company and the Technical University of Denmark students hope to commercialize the idea within a year. [Image Credit: © Cokolatetnica | Pixabay]

Danish technology students who were asked to find a sustainable process to recycle carrot peels and pulp have come up with a way to turn to it into flour. Vegetable supplier Greens Wholesale generates 100 tons of biological waste every month as it produces fresh juices and produce. Much of the waste is converted to biogas or fertilizer, but the company wanted to optimize its production process to reduce costs and perhaps turn a profit. Turning carrot waste into flour was the winning idea: it can replace up to half of the wheat flour in a recipe. The company and the Technical University of Denmark students hope to commercialize the idea within a year. [Image Credit: © Cokolatetnica | Pixabay]

Innovations

Blockchain-Based App Helps Atlanta Businesses Reduce Food Waste

A technology that allows distribution – but not copying – of digital information, blockchain was originally devised for the digital currency Bitcoin. Now a food waste management company in the Atlanta, Ga., area is using a blockchain-based app to connect businesses with local charities to ease deliveries of leftover food. The idea behind the Goodr app is to reduce food waste by providing data about what types of surplus food app users are producing. The Goodr app keeps a data ledger for clients showing how much food is wasted, and where they might be losing money. Data indicate what food gets wasted the most, what the community connections are, and how the environment is affected. Goodr hopes to expand to Seattle, Chicago, Los Angeles, Washington D.C., Miami, Dallas, Houston and San Francisco by the end of 2019.